CRYOGENIC CFMS 16

The CFMS-16 setup is designed for measuring transport, magnetic, and thermal properties of materials and nanostructures in a magnetic field range of up to 16 Tesla and temperatures down to 1.5 K.

| VTI shaft diameter | 30 mm |

| DC resistance measurements voltage range | from 10 nV to 100 V |

| AC resistance measurements voltage range | from 10 nV to 1 V |

| AC resistance measurements frequency | from 1 MHz to 100 kHz |

| Heat capacity measurements, sensitivity | 1 nJ/K at 10 K |

| Heat capacity measurements, sample | mass 1 µg – 200 µg, size 100 µm x 100 µm x 100 µm |

| Magnetic susceptibility measurements, sensitivity (at 1 kHz) | 10-5 emu/Gauss |

CRYOGENIC CFMS 5

The CFMS-5 setup is designed for measuring transport, magnetic, and thermal properties of materials and nanostructures in a magnetic field range of up to 5 Tesla and temperatures down to 1.5 K.

| VTI shaft diameter | 30 mm |

| DC resistance measurements voltage range | from 10 nV to 100 V |

| AC resistance measurements voltage range | from 10 nV to 1 V |

| AC resistance measurements frequency | from 1 MHz to 100 kHz |

| Heat capacity measurements, sensitivity | 1 nJ/K at 10 K |

| Heat capacity measurements, sample | mass 1 µg – 200 µg, size 100 µm x 100 µm x 100 µm |

| Magnetic susceptibility measurements, sensitivity (at 1 kHz) | 10-5 emu/Gauss |

21T cryomagnetic system

The system consists of high-field superconducting magnet mounted on a dedicated support assembly in a purpose made cryostat. The magnet is designed to produce a central field 21 Tesla when operated in conjunction with a lambda cooling loop fitted to the support assembly. The magnet is equipped with a superconducting switch, allowing it to operate in persistent field mode. The magnet support assembly is also designed to accommodate a He3 variable temperature insert (VTI) and a He4 insert. He3 VTI allows cooling down to 0.3 K by pumping helium-3 vapor. Samples can be placed on two types of holders: a fixed holder and a rotating platform. The system is also equipped with a module for vibrating sample magnetometry (VSM) and AC magnetic susceptibility measurements, enabling operation in the temperature range of 1.6-300K.

| Magnet | |

| Design operating field at 4K | 20 Tesla |

| Maximum operating field at 4K | 20.3 Tesla |

| Design operating field at 2K | 21.0 Tesla |

| Central field constant | 1632.01 Gauss/Amp |

| Central homogeneity (10mm DSV) | 102 |

| Current for 20.0 Tesla | 122.54 Amps |

| Current for 21.0 Tesla | 128.67 Amps |

| Inductance | 257.0 H |

| Clear bore | 40.0 mm |

| He-3 VTI | |

| Temperature range | 0.3 K – 300 K |

| Sample mounting area | 5 mm x 5 mm |

| No. of contact pins | 12 (fixed holder), 20 (rotating platform) |

| Maximum operating time at 300 mK | 24 hours |

| VSM an AC susceptibility | |

| Sample temperature range | 1.6 – 300 K |

| Range of the z-axis translation stage | 100 mm |

| Vibration amplitude (typical) | 2 mm |

| Vibration frequency (typical) | 20Hz |

| Noise base (10 sec averaging) | 10-5 emu |

| Accuracy and reproducibility | 0.5% |

| Dynamic range (standard) | 108 |

| Noise level | 5 x 10-6 emu/√Hz +B x 1 x 10-6 emu / T /√H |

| Max. allowed sample size | 4×10 mm2 |

| AC susceptibility frequency range | 1-10000 Hz |

| AC sensitivity at 1kHz | 10-6 emu at 4K |

Physical Properties Measurement System Quantum Design PPMS-9

| Base functionality | |

| Temperature | 1.85 – 400 K |

| Magnetic field | up to 9 T |

| Standard measurement options | |

| AC / DC charge transport | |

| Dynamic magnetic susceptibility | |

| Magnetic moment | Vibrating Sample Magnetometer (VSM) |

| Heat capacity | Relaxation calorimeter |

| Thermal conductivity and thermoelectricity | |

| Advanced features | |

| Sample rotation | |

| He-3 cryosystem | down to 0.35 K |

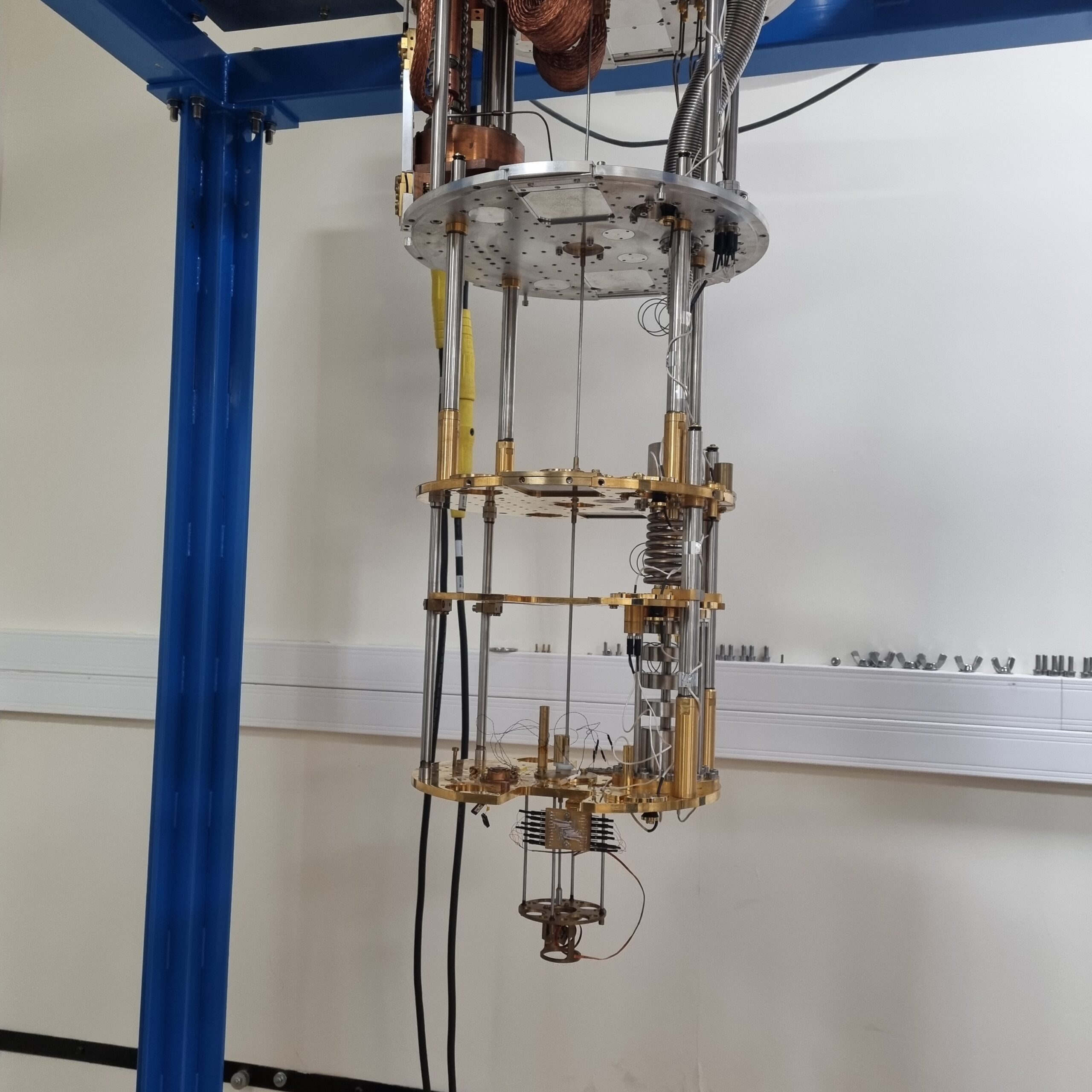

BlueFors LD250

The setup is designed for measuring the parameters of nanoelectronics elements, quantum logic cells, nanomechanics, nanophotonics, and quantum metrology at ultra-low temperatures. The setup includes a measurement complex of microwave equipment from Agilent and a helium-free dilution cryostat with a pulse tube model LD250 from BlueFors for achieving ultra-low temperatures.

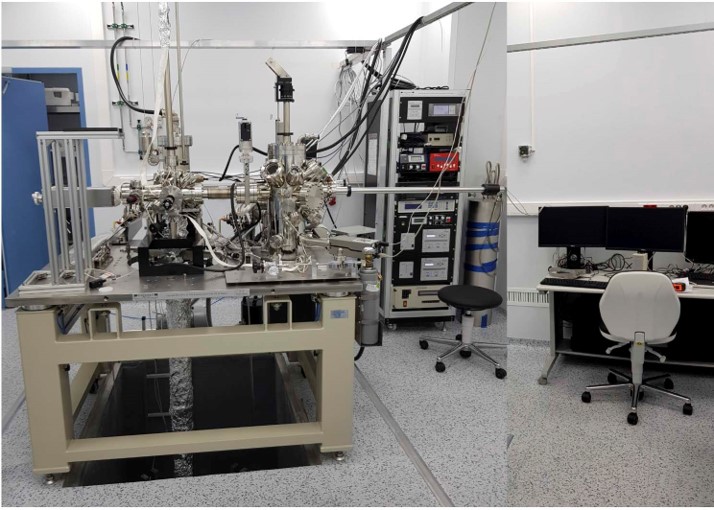

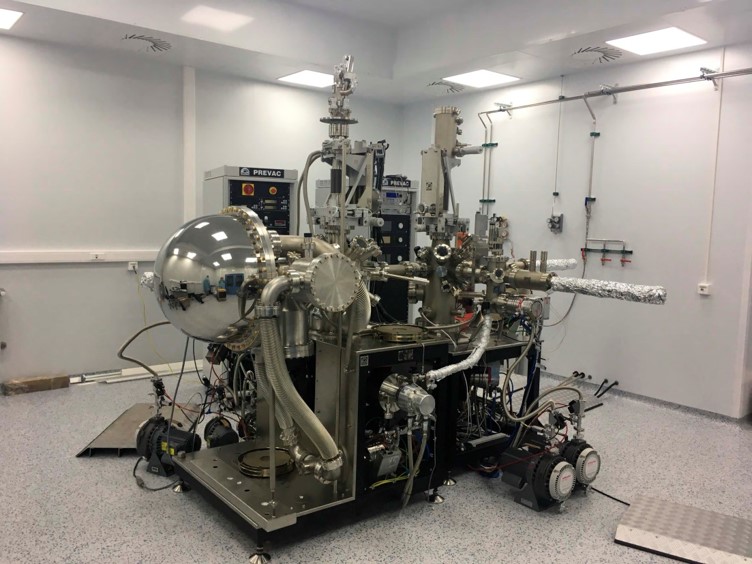

Low-temperature Scanning Tunneling Microscope Unisoku-1300

Tunneling Microscope (STM) makes it possible to measure the spectra of the electronic states of the studied materials in a wide temperature range: 350mK-300K. The measurement and preparation of the surface is carried out in an ultra-high vacuum (10-11 mbar). The installation provides four types of surface preparation of the material under study: cleavage, cryogenic cleavage, bombardment with argon atoms, and annealing in a high-vacuum chamber.

| Vacuum | 10-10 – 10-11 mbar |

| Temperature range | 350мК – 300К |

| Cryogenic cleavage | yes (at 77K) |

| Number of samples in preparation chamber | up to 4 |

| Transimpedance amplifier | Femto, TIA switched with amplification up to 109 V/A |

| STM control system | Nanonis |

Quantum Design MPMS-XL7

…

| AC Susceptibility | |

| Temperature Range | from 1.9 to 350 K |

| Sensitivity | 2 x 10-8 emu |

| Amplitude | 2 mOe ¸ 15 Oe |

| Frequency Range | 10 Hz ¸ 10 kHz |

| DC Magnetization sensitivity | 2.5 x 10-5 emu |

| Vibrating Sample Magnetometer(VSM) | |

| Temperature range | 1.9 – 400 K and 300 to 1000 K (with Oven) |

| Precision | 0.5 K |

| Magnetic field | up to 9 Tesla (Field uniformity 9 T: ±0.01 % over 3 cm on axis) |

| Field Resolution | 0.016 mT (0.16 G) |

| Oscillation frequency | 40 Hz |

| Oscillation amplitude | 2 mm peak – Range of 0.5 mm¸ 5mm |

| Sample Mass | < 1 gram |

| RMS sensitivity | < 10-6 emu and < 10-5 emu (with oven) |

| Heat Capacity | |

| Temperature range | 1.9 – 400 K |

| Sample size | 500 mg |

| Resolution | 10 nJ/K at 2 K |

| Thermal Transport | |

| AC Resistivity | Measured by using precision current source and phase-sensitive voltage detection (AC Transport) |

| Thermal Conductivity | Measured by applying heat from the heater shoe in order to create a user-specified temperature differential between the two thermometer shoes |

| Seebeck Coefficient | Measured by creating a specified temperature drop between the two thermometer shoes – just as it does to measure thermal conductivity |

| Electro Transport | Measures AC resistivity; Hall effect; I-V curve |

High Resolution Infrared Fourier-transform Spectrometer IFS 125HR

| Spectral range | 11000 – 8 cm-1 | 0.9 – 1250 mm |

| Resolution | Better than 0.0063 cm-1 |

| Resolving power | Better than 106 |

| Wavenumber accuracy | Better than 5∙10-7 x wavenumber (absolute) | 1∙10-7 (relative) |

| Photometric accuracy | 0.1% T |

| Aperture | f/6.5 |

| Scanner speeds | 0.16-2.5 cm/s |

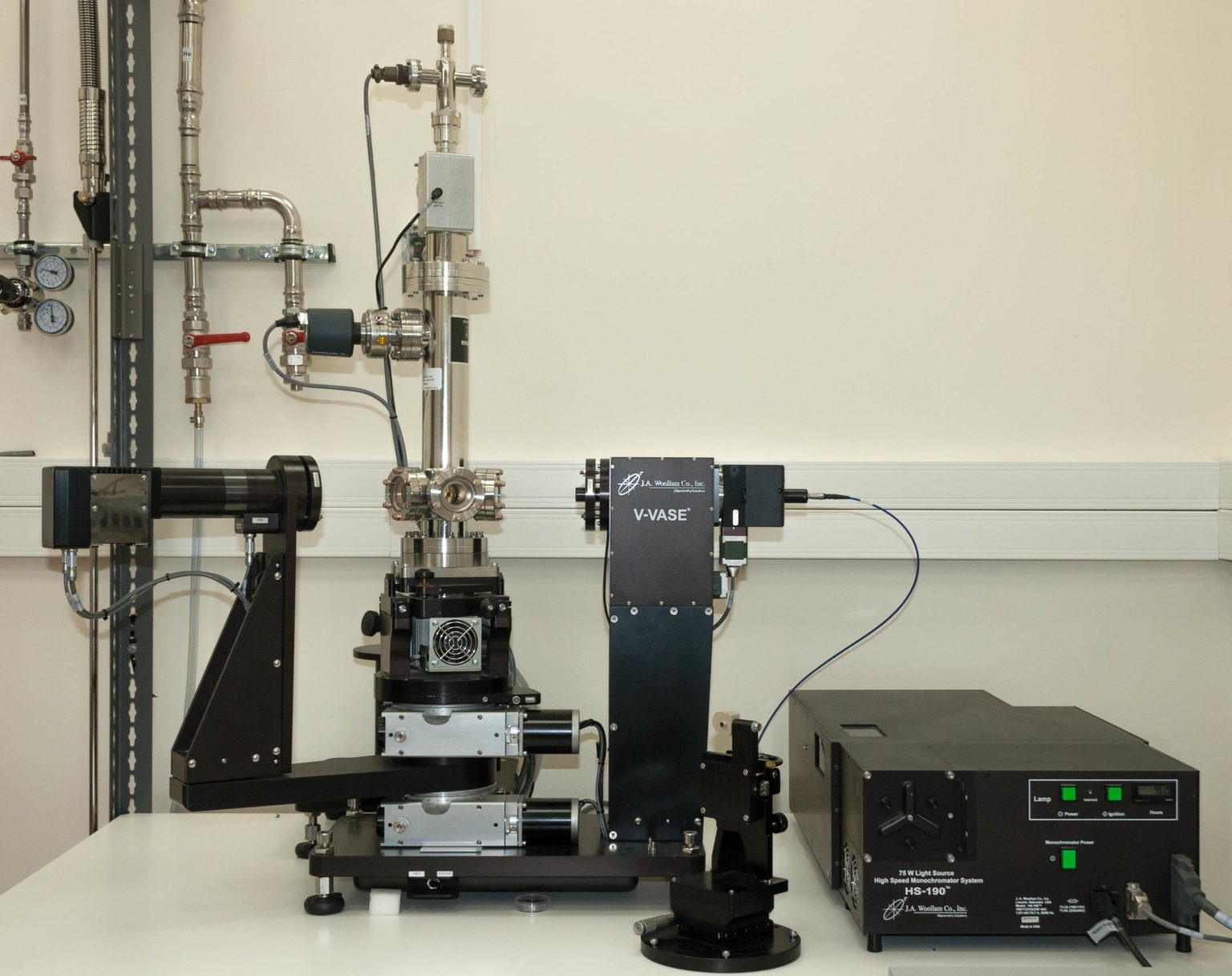

Spectral ellipsometer J.A. Woollam VASE

Determination of the optical properties of bulk and film samples of metals, dielectrics and semiconductors in the wavelength range 193-2500 nm (complex refractive index, dielectric constant, film thickness of materials with known optical constants) at temperatures 4.2-500K.

| Spectral range | 193 – 2500 nm |

| Spectral resolution | 0.3 Å |

| Data acquisition rate | 1 – 3 s per wavelength |

| Accuracy of the fully-automated goniometric platform that provides the independent movement of the sample and detector | 0.01° |

| Angle range of the fully-automated goniometer | 15° – 90° (reflection) | 0° – 90° (transmission) |

| Accuracy of the build-in four quadrant detector that provides an accurate setting of the sample angle | up to 0.001° |

| Measurement accuracy Y | 45° ± 0.03° |

| Measurement accuracy D | 0° ± 0.02° |

| Reproducibility for the sample 30 nm SiO2/Si | Y = ± 0.015° | D= ± 0.08° |

| Minimum dimensions of the samples studied | down to 2 mm |

| Accuracy of the refractive index determination of the bulk sample | 0.005 @ 1 mm |

| Accuracy of determination of the absorption coefficient | @ 1 mm |

| Absorbing sample | 0.005 |

| Transparent sample | 0.05 |

| Temperature adjustment range of the sample | 4.2 – 500K |

| Accuracy of the temperature setting | ± 0.1K |

Tensor 27

Measurement of transmission and reflection spectra in the mid-IR range (7500-370 cm-1, 1.3-27 µm)

| Spectral range | 7500 – 370 cm-1 |

| Spectral resolution | 0.5 cm-1 (with apodization) |

| Wavenumber accuracy | 0.01 @ 2000 cm-1 |

| Photometric accuracy | 0.1% T |

System for angle-resolved photoemission spectroscopy (ARPES)

A system for measuring electron photoemission spectra with angular resolution and measurement of spin projections based on a hemispherical electron-optical energy analyzer and a monochromatic photonic source of the ultraviolet range, equipped with a helium-cooled sample manipulator

| Scienta R4000 energy analyzer | |

| Energy resolution | 17 meV |

| Angle resolution | 0.1° |

| VUV5k light source | |

| He Ia line (wavelength/energy) | 584 А / 21 eV |

| He Ib line (wavelength/energy) | 537 А / 23 eV |

| He II line (wavelength/energy) | 304 А / 41 eV |

| Sample preparation chamber | |

| Analytics for surface characterization of samples | LEED and Auger Spectroscopy Unit |

Rigaku MiniFlex 600 powder diffractometer

The MiniFlex benchtop X-ray diffractometer is a multipurpose powder diffraction analytical instrument that can determine: crystalline phase identification (phase ID) and quantification, percent (%) crystallinity, crystallite size and strain, lattice parameter refinement, Rietveld refinement, and molecular structure. It is widely used in research, especially in material science and chemistry, as well as in industry for research and quality control.

| X-ray source | Co (λ Kα = 1.79021 Å) |

| Tube output voltage | 20 – 40 kV (step 1 kV) |

| X-ray source output current | 2 – 15 mA (step 1 mA) |

| High voltage generation method | Cockcroft-Walton high-frequency method |

| Stability | Within ±0.05% for tube voltage and tube current, taking into account input power fluctuation of ±10% |

| Applicable X-ray tube | Toshiba A-21, A-41, PANalytical PW22XX, etc. |

| Focus and position control mechanism | ±1 mm, infinitely adjustable through the use of a spring plate |

| X-ray diaphragm | Mechanical rotating diaphragm |

| Kβ radiation filter | Nickel filter for copper tube, standard thickness 0.015 mm, Iron filter for cobalt tube. |

| X-ray exit angle | 6°, fixed |

| Goniometer | Vertical θ/2θ |

| Goniometer radius | 150 mm |

| Scanning axis | θ/2θ linked |

| Scanning range 2θ | −3° to +145° |

| Measuring range 2θ | +2° to +145° |

| Minimum axis pitch angle θ/2θ | 0,005° (2θ) |

| Positioning speed | 500° / min (2θ) |

| Scanning speed | 0,01 – 100 ° / min |

| Reference angle | 2θ = 10° |

| Divergence slit | 1,25° |

| Beam width | 10 mm |

| Soller slits on the incident beam | 2,5° |

| Divergence slit | 1,25° |

| Soller slits on the diffracted beam | 2,5° |

| Receiving slit | 0,3 mm |

| Monochromator on the diffracted beam | Graphite |

| Detector | Scintillation counter |

| Effective window diameter | 23 mm |

| Working with sensitive samples | Hermetic sample holder |

Tongda TD-5000 single crystal diffractometer

TD-5000 single crystal X-ray diffractometer is mainly used to measure the three-dimensional spatial structure and electron cloud density of inorganic and organic materials. The structure of special materials such as twins, in-commensurate crystals and quasi-crystals were analyzed and the accurate three-dimensional space (including bond length, bond angle, configuration, conformation and electron density) of new compounds (crystal) was determined. It can provide crystal cell parameters space group, crystal molecular structure, hydrogen bond and weak interaction information, molecular configuration and conformation information.

| Microfocus X-ray source | |

| Anode material | Mo (λ Kα = 0.71069 Å) |

| Power | 50 W |

| Focal spot size | 91×139 um2 |

| Beam divergence | 6 mrad |

| Monochromator for Kα1/Kα2 duplex separation | Yes |

| X-ray optics to increase radiation intensity | Yes |

| X-ray source generator operating voltage | 10 – 60 kV |

| Operating current of the X-ray source generator | 10-864 uA |

| Radiation power deviation of the X-ray source for 8 hours after 30 minutes of warm-up time | 0,06 % |

| Two-dimensional hybrid pixel detector | |

| Detector sensor size | 83.8×67 mm |

| Detector pixel size | 172×172 um |

| Number of detector matrix pixels | 487×407 |

| Total number of detector matrix pixels | 198209 |

| Maximum detector readout frequency | 20 Hz |

| Detector readout time | 7 ms |

| Range of detector readout energies | 3,5-18 keV |

| Vertical four-circle kappa goniometer | |

| Minimum positioning and scanning step in goniometer axes | 0,0001° |

| Scanning mode | Step, continuous, segment, transmission |

| Number of sample rotation planes | 3 |

| Number of rotation planes of the detector | 1 |

| Distance from specimen to detector | 35 – 145 mm |

| Goniometer head | With sample position adjustment in X, Y, Z axes |

| Chi axis resolution | 0,005° |

| Phi angle value | -360° to +360° |

| Phi axis resolution | 0,005° |

| Omega angle value relative to Theta | -90° to +90° |

| Omega axis resolution | 0,00125° |

| Theta angle value | -65° to +105° |

| Theta axis resolution | 0,00125° |

| Kappa angle value | -72° to +72° |

| Kappa axis resolution | 0,0025° |

| Diameter of the sphere of axis mismatch | 7 um |

| Sample temperature control system | |

| Temperature control temperature | 100 – 300 К |

| Temperature control accuracy | 0,3 К |

JEOL JSM-7001F scanning electron microscope

JEOL JSM-7001F is an autoemission scanning electron microscope, which by using a field-emission electron gun (Schottky cathode), advanced imaging technology and computer technology, not only allows one to observe the fine structure of the sample surface with high resolution (3nm), but also to perform various analyses: local analysis of elemental composition (1µm2) by energy dispersive spectrometry (EDS), cathodoluminescence analysis (CL) and analysis of crystallite orientation by backscattered electron diffraction method (EBSD).

| Resolution in secondary electrons | 1.2 nm (at an accelerating voltage of 30 kV); 3.0 nm (at an accelerating voltage of 1 kV). |

| Spatial resolution in elemental mapping | 3.0 nm (at an accelerating voltage of 15 kV, working distance of 10 mm, probe current of 5 nA). |

| Magnification in SEM mode | x10 to x1 000 000. |

| Magnification correction | Automatic correction according to the accelerating voltage and working distance. |

| Imaging modes | – image in secondary electrons; – reflected electron image in the atomic number contrast mode; – reflected electron image in the topographic contrast mode. |

| Accelerating voltage | – 0.5 to 30 kV (normal mode); – 0.5 to 2.9 kV in 10 V steps; – 2.9 to 30 kV in 100 V steps; – 0.2 to 30 kV (low-voltage mode). |

| Probe current | 1×10-12 to 2×10-7 A |

| Type of stage | fully eucentric table with angle gauge and backward correction. |

| Stage movement ranges | |

| Axis X | 70 mm |

| Axis Y | 50 mm |

| Axis Z | 3 to 41 mm (continuous) |

| Tilt T | -5 to +70 |

| Rotation R | 360, continuous |

| Standard sample holders | for 12.5 mm diameter specimens 10 mm thick; for 32 mm diameter specimens 20 mm in thickness. |

| Sample chamber | 10-4 Pa (standard mode); there is a possibility of operation in high-vacuum mode using a cold bus fed with liquid nitrogen and in low-vacuum mode. |

| Elemental Analysis | Inca X-Act energy dispersive spectrometer |

| Elemental Analysis Detector | Analytical solid state drift detector (SDD) |

| Cooling | Peltier element |

| Functions | – automatic peak detection – four modes of spectra acquisition; – quantitative analysis; – in-plane element distribution maps (SmartMap) |

| Detectable elements | From beryllium (4Be) to plutonium (94Pu) |

| Guaranteed resolution | 60 eV at C Kα and 130 eV at Mn Kα |

| Peak position stability | less than 1 eV on Mn Kα |

| Resolution stability | less than 1 eV on Mn Kα at 1,000-100,000 imp/sec |

| Concentration sensitivity | less than 0.1% |

| Measurement range of mass fraction of elements, % | 0.1 to 100 |

| Detector active area, mm2 | 10 |

| Determination of crystallite orientation | Electron backscattered diffraction (EBSD) method by HKLNordlys |

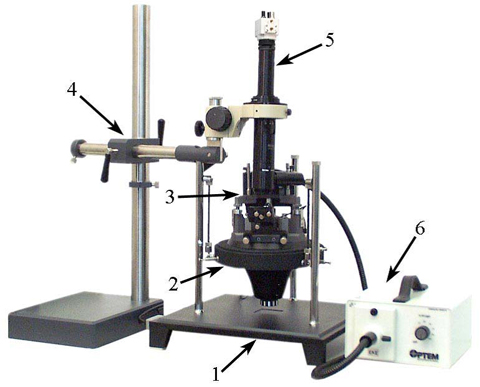

Trinocular Microscope ICM-100BD

For precision alignment of microobjects.

| Mobility | с подвижной головой |

| Lenses | 5х,10х,20х,50х,100х. |

| Eyepieces | 10х |

| Field | Light/Dark |

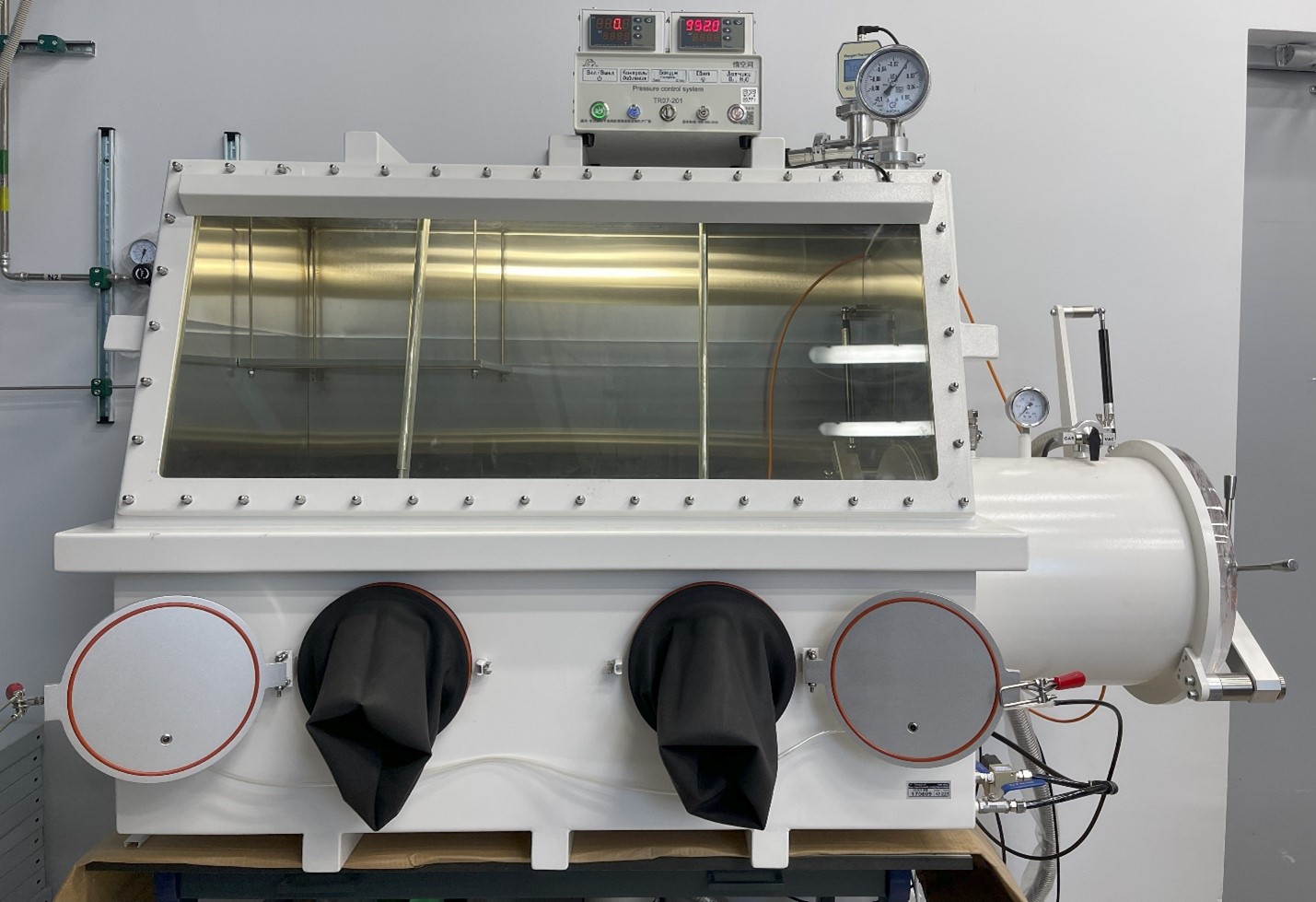

twinned glove boxes with high-purity argon atmosphere

Two pieces of twinned glove boxes with high-purity argon atmosphere with analytical balances, hydraulic press and digital microscope for sample disassembly and mounting.

Intended for work with sensitive materials (alkaline and alkaline-earth, rare-earth metals) in high-purity inert gas environment without access of oxygen and water.

The working medium is argon.

The content of oxygen and water vapor in the working medium is less than 0.1ppm.

The size of the small antechamber for specimens and instruments insert is 145 mm inner diameter and 355 mm length.

The size of the large antechamber for the insert of additional equipment – inner diameter 370 mm, length 745 mm.

Vacuumable glove box with nitrogen atmosphere

Allows one to work with additional equipment and open ampoules in an oxygen-free environment.

The working medium is nitrogen.

The content of oxygen and water vapor in the working medium is less than 1ppm.

Sample and instrument antechamber size – inner diameter 345 mm, length 460 mm;

Retsch Cryomill Vibrating mill

The CryoMill is a laboratory ball mill specifically designed for this application. It features an integrated cooling system which continually cools the grinding jar with liquid nitrogen before and during the grinding process. Thus, the sample is embrittled and volatile components are preserved. The liquid nitrogen is continually supplied from an autofill system in the exact amount required to keep the temperature at –196 °C.

| Initial particle size | <= 8 mm |

| Final fineness | ~ 5 um |

| Usable volume | Max. 20 ml |

| Number of grinding jars | 1 |

| Vibration frequency | 5 – 30 Hz (300 – 1800 rpm) |

| Dry grinding | Yes |

| Wet grinding | Yes |

| Cryogenic grinding | Yes |

| Grinding jar material | Stainless steel |

| Grinding jar volume | 5 ml, 35 ml, 50 ml |

Fritsch Pulverisette 7 Premium Line Planetary mill

The Planetary Micro Mill PULVERISETTE 7 premium line with 2 grinding stations is designed for a broad range of applications and ideally suited for loss-free grinding down to a final fineness of 100 nm of hard, medium-hard and brittle materials. Depending on the desired final fineness, the grinding can be performed dry, in suspension or in inert gas. In addition to comminution, one can also use the mill for mixing and homogenising emulsions and pastes or for mechanical activation and alloying in materials research.

| Initial particle size | 5 mm |

| Average grinding fineness | Up to d50 < 0,1 um |

| Number of grinding jars | 2 pcs |

| Frequency ratio of planetary and cup rotation | 1:-2 |

| Rotational frequency of the planetary disk | 150 – 1100 rpm |

| Maximum acceleration | 928 m/s2 (94,6 g) |

| Reverse drive | Yes |

| Grinding jar volume | 20, 45, 80 ml |

| Grinding jar material | Tungsten carbide, zirconia |

Powteq BM6 Pro Planetary mill

Planetary Ball Mill BM6Pro is suitable for dry and wet grinding and mixing some soft, hard, brittle and fibrous samples, which is used wherever the highest degree of fineness required, as well as the grinding result is reproducible. Apart from the classical mixing and size reduction processes, the mill also meet all the technical requirements for colloidal grinding.

| Initial particle size | 10 mm |

| Achievable average grinding fineness | Up to d50 < 1 um |

| Average dry grinding fineness | Up to d50 < 20 um |

| Wet (colloidal) fineness | Up to d50 < 0,1 um |

| Number of grinding jars | 1 pc |

| Frequency ratio of planetary and cup rotation | 1:-2 |

| Rotational frequency of the planetary disk | 100 – 650 rpm |

| Maximum acceleration | 602 m/s2 (61,4 g) |

| Reverse drive | Yes |

| Grinding jar volume | 250 ml |

| Grinding jar material | Stainless steel |

Furnaces

Various furnaces for crystal synthesis and growth, including tube furnace up to 1700°C, tube furnace with a rotary furnace, muffle furnaces up to 1250°C with various gas and vacuum capabilities

| Tmax, °C | Environment | |

| Tube rotary furnace | 1350 | Vacuum, Argon, Nitrogen, Air, Ar+H2(5%), Oxygen |

| Tube high-temperature furnace | 1750 | Vacuum, Argon, Nitrogen (up to 1300°C), Air (up to 1300°C), Ar+H2(5%), Oxygen (up to 1500°C) |

| Muffle furnaces | 1250 | Air, Gas flow (Argon, Nitrogen) |

Edmund Buhler MAM-1 argon arc melting unit

For oxygen-sensitive samples to be handled and alloyed in inert gas atmosphere.

1. Melting chamber and movable electrode inside the chamber

2. Designed for melting samples of approx. 5-20 g up to 3500°C,

3. sufficient for most laboratory purposes

4. Arc burning media – argon, argon-hydrogen mixture (5%), helium.

High temperature centrifuge for melt decanting

| Maximum speed | 3500 rpm |

| Maximum volume of the substance to be separated | 3000 ml |

| Maximum acceleration | 2780 m/s2 (283 g) |

| Centrifuge chamber temperature indication range | 0 to 150°C |

| Maximum ampoule length | 130 mm |

Optical zone melting furnace Crystal Systems FZ-T-4000-H

Crystal Systems FZ-T-4000-H is a four mirror optical floating zone furnace. Temperature distribution around the horizontal plane can be drastically homogenized and can be applied to the growth of high-quality single crystals.

| Maximum specimen diameter | 50 mm |

| Maximum specimen length | 150 mm |

| Lamp type | Halogen |

| Number of lamps | 4 |

| Vacuum | Up to 5*10-5 Hg mm |

| Pressure | Up to 10 bar |

| Maximum temperature | 2150 °С |

| Lamp power | 300, 500 и 1000 W |

| Length of molten zone | Up to 50 mm |

| Growth rate | 0,05-27 mm/h |

| Speed of slow molten zone movement | 0,05-27 mm/h |

| Speed of fast movement of the molten zone | 6-60 mm/min |

| Rotation speed of the holder | 5-55 rpm |

| Observation | Camera and Monitor |

| Growth work environment | Argon, Nitrogen, Oxygen |

PLD/MBE laser sputtering machine model PVD-2300

The PLD/MBE 2300 machine is designed to grow epitaxial films, monolayer film structures, and/or combinatorial thin films and can be easily integrated with a wide range of other sputtering techniques such as magnetron sputtering, effusion cells, ozone generators, and atomic or ion sources. These unique systems allow the user to utilize multiple deposition techniques in a small area to grow unique film structures. The machine produces films of various materials by vacuum atomizing a target of desired composition focused excimer laser radiation (laser ablation method).

| Substrate sizes | 5×10 mm, 10×10 mm, and 2-inch |

| Substrate sizes | 950°C (in oxygen) for Si, 850°C for transparent substrates (sapphire) in non-contact mode |

| Substrate sizes | ± 8°C on a 2-inch diameter substrate |

| Operating pressure range | from 5×10-9 Torr to 400 mTorr |

| Number and size of targets | Six 2-inch targets |

| Number and size of targets | From 50 mm to 100 mm |

| Number and size of targets | 60o |

| Laser | Eximer (KrF) with 248 nm |

| Pulse frequency | 50 Hz |

| Pulse frequency | oil-free (turbo pump and volute pump) |

| Residual pressure limit in the chamber max. | 5·10-7 Torr |

| Residual pressure limit in the chamber max. | optical pyrometer |

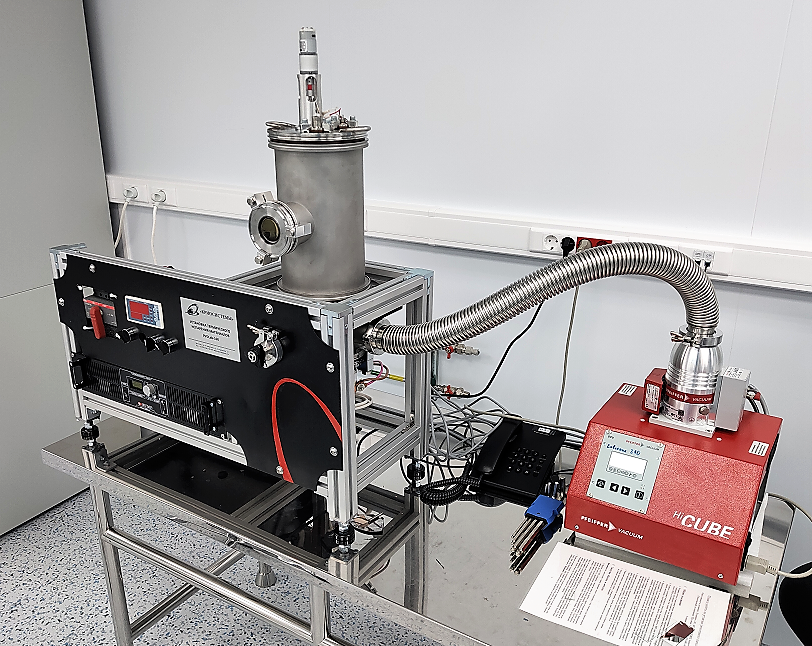

tubular furnace KJ-T-1200

Components:

The equipment is a tubular furnace with a hole diameter of 60 mm with a controller for temperatures up to 1200 C, a vacuum pumping system and regulation of gas supply and a digital control station. It is fully functional and actively used.

The installation is configurable, in particular it is used for:

1. Annealing of samples of layered materials in vacuum;

2. Application of a parylene coating by CVD.

The gas flow control unit is used in a plasma chemical etching unit.

Linde Model 1410 Helium Gas Liquefier

The principal components of the standard system are a Linde Model 1410 Helium Gas Liquefier and Model RSX Helium Screw Compressor.

Liquefier can liquefy with or without liquid nitrogen precooling, depending upon load requirements.

OPERATING PRINCIPLE

In operation, helium gas is compressed and delivered to the liquefier module at approximately 16.5 bar and returned to the compressor at close to room temperature and at a nominal pressure of 0.05 bar(g).

The gas is cooled in the liquefier by:

1. Liquid nitrogen when the precooler is used;

2. Heat transfer in the main heat exchanger;

3. Isentropic work extraction in the two expansion engines;

4. Isenthalpic expansion in the Joule-Thomson valve.

All of these processes take place in a high vacuum insulated chamber.

The liquid helium produced is delivered to an externally located liquefaction dewar via a removable vacuum insulated delivery tube.

Helium Gas Liquefier capacity is up to 40 liters per hour.

Vacuum automatic drying cabinet AKTAN VTSh-K52-250-PNS

Laboratory vacuum automatic drying cabinet AKTAN VTSh-K52-250-PNS can be used for drying of thermosensitive materials under controlled vacuum conditions, quick drying, degassing, evaporation, heating of metal parts for surface treatment, polymerization, testing, barometer calibration, degassing to eliminate air bubbles.

| Heating mode | Direct shelf heating |

| Working temperature, °С | +70 to 230 |

| Maximum temperature, °С | Up to 250°С |

| Vacuum limit | <1,33 mbar (133 Pa) |

| Temperature accuracy | 0,1°С |

| Temperature fluctuation | Less than ±1°С |

| Heating time | ≤ 40 min |

| Chamber material | Polished stainless steel SUS304 |

| Shelves material | Corrosion-resistant aluminum 5083 |

| Heater material | Electrothermal micaceous plates |

| Window | Bullet resistant tempered glass |

| Vacuum gauge | Digital, accuracy class of 0,25 |

| Working media | Argon (99,998%), Nitrogen (>99%), under request (He, Ar+5%H2, Air) |

| Working gas inlet | Manual and electric surge device |

| Vacuum system | Two-stage rotary vane vacuum pump, pumping speed 4 l/s (14,4 m³/h) | Inlet filter |

| Temperature control mode | Multistage PID temperature controller, independent temperature control on each shelf |

| Timer | 0-9999 min/0-9999 h (adjustable time) |

| Control function | Fixed value operation, normal operation, automatic stop |

| Fixed value mode | Simultaneous temperature and vacuum control |

| Program mode | Simultaneous temperature and vacuum control, 30 operating modes |

| Chamber dimensions (WхDхH, mm) | 450х450х450 |

Magnetron sputtering and thermal evaporation coating unit

The vacuum unit manufactured by Torr International is designed for applying metal, oxide and other coatings and thin films to various substrates using thermal or magnetron sputtering methods.

- The installation provides heating and rotation of the substrates during the spraying process.

- The installation provides continuous monitoring of the deposition process using a quartz thickness gauge.

- Additionally, an ion cannon is installed in the chamber for etching and cleaning the substrates before deposition.

- Magnetron sputtering is possible from three sources, two of them have RF power sources.

- The electronic evaporator is equipped with a carousel for 4 crucibles.

- The thermal evaporator is a tungsten boat.

- All sources are equipped with dampers that reduce the likelihood of mutual contamination of sources.

Helios NanoLab 660 FEI

Scanning electron-ion microscope Helios NanoLab 660 is designed to measure the linear dimensions of the topology elements of the microrelief of the surface of solid-state materials and to carry out local structural modification of the surface of solid-state objects with an ion beam.

Micromanipulator Kleindiek MM3A-EM

The micromanipulator works as the SEM (FEI HELIOS660) subsystem. It is designed for manipulating microflakes in the SEM camera, their precise positioning and movement. The manipulator significantly expands the capabilities of the system, allowing independent interaction with various parts of the sample in a single load.

Micromanipulator Kleindiek MM3A-EM

The lithograph works as the SEM (FEI HELIOS660) subsystem.

Main features and features:

Scanning Tunneling Microscope Solver-Pro NT-MDT

Solver- P47-PRO is a universal measuring unit for studies with high spatial resolution in normal atmosphere, in liquid media and in a various gas atmosphere, at temperatures up to 150C.

| Sample Size | 40х40х10мм |

| Scanners | 3´3´1mcm (±10%) 10´10´2mcm (±10%) 50х50х3 мкм (±10%) |

| Minimum scan step | 0.0004nm; 0.0011nm; 0.006nm |

| Scanning method | By sample |

| Scanning probe heads | AFM STM 30pA-50nA, mrs noise 4pA (сwith a standard preamplifier) 10pA-5nA, mrs noise 1.5pA(low current preamplifier) Shear Force |

| Optical system | Aperture 0.1 Magnification – from 58´ to 578´ Horizontal visible field from 5.1 to 0.51 mm |

| Monitoring and management system | SPM controller |

| Vibration isolation | Passive insulation installed Active vibration insulation system |

Electron beam spraying system MEB-400

The units are designed for spraying thin metal films, including those made of various metals without vacuum rupture, by electron beam spraying. Additionally, the MEB-500 installation has the ability to spray at different angles, in-situ oxidation in the chamber, and cleaning (etching) with ions.

| Maximum vacuum (mmHg) | 10-7 |

| Number (volume) of cells in the evaporator | 6 (7ccm) |

| Substrate Temperature (Co) | up to 150 |

| Metals | Al, Nb, Ti, Co, Pt |

| Additional processes | — |

The main directions of research conducted using the device:

The installations are mainly used to create superconducting nanoelectronics devices, create contacts and electrodes for microscopic samples, labels, tunnel junctions from Al2O3. As a rule, spraying is carried out through shadow stencil masks or masks made of photo/electronic resist.

Electron beam spraying system MEB-550

The units are designed for spraying thin metal films, including those made of various metals without vacuum rupture, by electron beam spraying. Additionally, the MEB-500 installation has the ability to spray at different angles, in-situ oxidation in the chamber, and cleaning (etching) with ions.

| Maximum vacuum (mmHg) | 10-8 |

| Number (volume) of cells in the evaporator | 6(15 ccm)+2(7ccm) |

| Substrate Temperature (Co) | up to 700 |

| Metals | Al, Nb, Ti |

| Additional processes | oxidation, Ar etching, spraying at an arbitrary angle. |

Additional information:

Superconducting nanoelectronics involves the creation of devices of submicron sizes, on a single chip. To create such devices, one of the most important elements is the Josephson transition. The proven and best controlled method of manufacturing such a transition is the acidification of aluminum with further spraying of the next layer of metal without breaking the vacuum. To combine such a transition with planar technology, it is necessary to rotate the sample in a vacuum, as well as the possibility of ion surface treatment. All these features are combined by the MEB550 installation from the world leader — the French company Plassys. Working with high-quality superconducting metals: Nb, Al and Ti closes the possibilities of spraying many other materials in the same installation, for example, fusible or magnetic. Therefore, we have several spraying plants for different metals.

Thermal spraying

Installation for the deposition of materials in vacuum. The installation is fully functional and is actively used for applying electrical contacts to the test samples and making shadow masks.

- The vacuum unit (brand) is designed for applying chromium and gold, including sequentially without breaking the vacuum;

- It has a vacuum (turbopump) of the order of 10-5 mbar;

- The evaporator current is 120 A (designed for operation with chrome rods and evaporation from the boat);

- The distance from the source to the sample is adjustable — 5-20 cm.

Plasma chemical purification plant

For cleaning and surface treatment of nanostructures in low-density oxygen plasma.

In the photo, the plasma chemical purification unit stands on the air distribution cabinet. Next to them is the ultrapure oxygen generation unit (99.999%) Coulomb-10K.