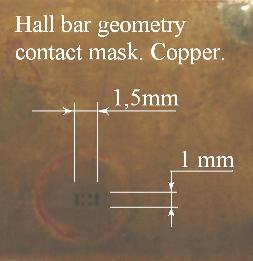

Principle of operation:

Cutting the mask of a metal foil is made by a tungsten needle. The needle and the foil connected to the output of the HF generator and immersed into distilled water. At the point of contact there is a spark, burning through the foil. Cutting thickness is limited by the thickness of the tungsten wire (50 micrometers). Standard size foil 2cm, masks – 8mm. It is possible to make bigger masks.